Goals are critical for any business, including the fabrication industry. Without them, it’s like playing a game of darts in a pitch-black room. You keep aiming and throwing, but you have no idea if you’re ever going to hit the bullseye.

That’s where KPIs come in.

Key Performance Indicators (KPIs) are indicators that track your progress toward a specific goal. KPIs give your business focus – something to work towards. According to Peter Drucker, “What gets measured gets done.”

In this quick guide, we’ll go over how to set and track KPIs that matter for your countertop shop.

What are KPIs?

KPIs help you track the health of your company. For example, here at Moraware, we track new customer activity as a measure of success. Why? Because we’ve found that if our new customers aren’t active within the first few weeks, they aren’t likely to be active at any point and will cancel.

That’s one KPI we measure and report on that directly affects the way we do business. What metrics are important for your business?

First and foremost, you want to make sure it can check a few boxes. Here are a few features of a great KPI:

- You should be able to tell if you’re making progress toward your goal

- Your measurements along the way should help you make better business decisions

- You should be able to compare performance change over time – for example, sales this month versus sales this month last year

A KPI can track efficiency, effectiveness, quality, timeliness, governance, compliance, behaviors, economics, project performance, personnel performance, or resource utilization.

What KPIs Should I Have?

There are ideally five areas of your business you want to be tracking with KPIs:

- Strategic Measures: You’re tracking progress toward a strategic goal.

- Operational Measures: You’re tracking day-to-day operations and tactics.

- Project Measures: You’re tracking project progress and effectiveness.

- Risk Measures: You’re tracking the risk factors that can threaten your company’s success.

- Employee Measures: You’re tracking your team’s performance.

Many industries have staff members dedicated to tracking data and analytics because as you can tell, there can be KPIs for every aspect of your business.

It can be a lot to track and measure but don’t get overwhelmed with all the possibilities. You don’t have to tackle all of this at once.

Examples of KPIs for Countertop Shops

You have to start somewhere, so here are a few ideas of KPIs worth tracking in the fabrication industry:

- Quotes per day/month/quarter/year

- Leads per day/month/quarter/year

- Jobs per day/month/quarter/year

- Templates per day/month/quarter/year

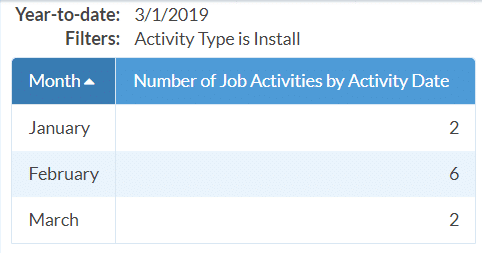

- Installs per day/month/quarter/year

- Number of employees

- Average annual sales per employee

- Amount spent on stone

- CNC utilization

- Hand finishing productivity

- Remakes and reworks

- Customer complaints

- Upsells

- Overall equipment effectiveness

- Overtime as a percentage of total hours

- Profit margin

- Planned work to total work ratio

This is a lot of options, and it’s really only scratching the surface.

But here’s the deal: when it comes to KPIs, it’s all about the quality of them, not the quantity. If you have five solid KPIs and you’re tracking them accurately, that’s so much more valuable than 20 KPIs that are irrelevant or based on faulty data.

The good news? Many of the KPI examples above can be tracked using the data you’re already entering in CounterGo and/or Systemize.

Don’t Forget KPIs For Each Employee

We often think about KPIs for the health of the company, but don’t neglect KPIs for each employee. They need to know if they’re doing their job and are meeting expectations. Plus, the work of each employee ultimately contributes to the overall goal.

Geoffrey Gran, Owner of The Countertop Factory Midwest, says he gives KPIs to all employees: “It might be a square foot goal, a quality control goal, whatever it might be,” he says. “If you give everyone transparency, they will move mountains for you.”

Further Reading: How to Hire Quality Talent for Your Countertop Company

Where Do You Stand?

As somewhat of a side note, it’s worth taking a look at the latest MIA Fabricator Benchmarking Report. It can show you how some of your company’s KPIs match those of other fabricators.

For example, how many employees do you have? The average number of employees for a manual shop is 10, while automated shops average just over 38.

What are your annual sales? The average annual sales for a manual shop is $1,420,175, and an automate shop averages $6,456,569.

It can be helpful to see where you stand, so take a look at that report if you haven’t already.

How Do I Track KPIs?

Before you can measure your business, you must have systems and processes in place. Once you have those processes in place, you can establish measurements to make sure they’re being done consistently.

Paul Menninger, Owner of Capitol Granite, said it best on our StoneTalk podcast: “When you begin to grow, you need to have a database whereby you are monitoring and measuring those key performance indicators that are most important to the shop owner.”

If you’re only doing 1 or 2 jobs per week, you can reasonably track KPIs manually. But as you grow, you really need a system in place that can do the heavy lifting for you.

That’s where Moraware comes in, and as long as you’re entering good data, extracting it and using it isn’t that hard.

Get extra help with these consultants

If you want to scream into a pillow when you look at a spreadsheet full of data, you might consider contacting one of our Partners.

BPMetrics offers real-time KPI reporting metrics to both management and production-floor staff, directly driving your ROI. Employees can see where they are in real-time to know if they are on target to meet the production targets.

Scott Hanes, Owner/CEO Majestic Marble & Granite, says his team witnessed a 20% increase in productivity.

Kim Duda of Duda Consulting can also help you sort through your data in Moraware software. Having good data is a prerequisite to tracking your KPIs.

“Really, it’s making the data you’re already entering work for you so you can utilize it to make better business decisions,” Kim says.

Conclusion

So many business owners go through the day-to-day motions without identifying goals or KPIs. But if you’re not tracking your shop’s data, how do you know where you stand?

If you don’t know how much money you’re making, how can you push yourself to reach a new revenue goal? If you don’t know which employee is costing you the most in reworks and remakes, how can you remedy it?

We could go on and on, but really, KPIs are critical to the health of your shop. Spend some time identifying which KPIs to start with.

And if you haven’t already, schedule a demo for CounterGo, our quoting software, and Systemize, our scheduling software. These will change the way you do business, and they also make it possible to track KPIs without disrupting your process at all.

Related Reading: