It’s common for most countertop fabricators to work in both residential and commercial settings, typically with an emphasis tilting toward residential work. Then there is the much smaller group of fabricators who specialize in residential-only projects. Rarer still are the handful of countertop companies whose focus is strictly on the commercial sector. And while the tools and fabrication techniques are practically identical between residential and commercial projects, the role of the fabricator as a design and materials consultant with the end-user is vastly different.

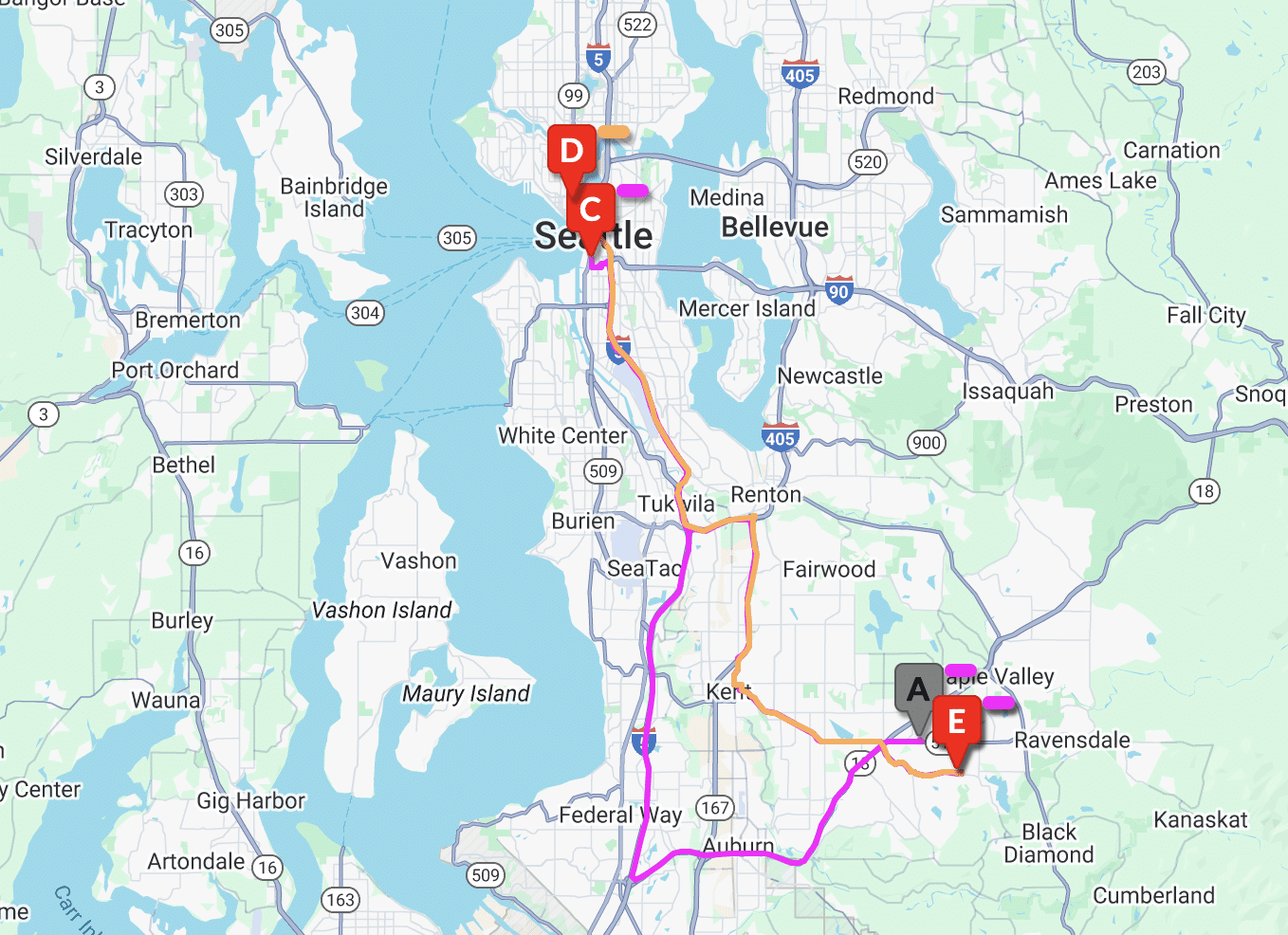

“Often in commercial construction when you’re executing the work, you’re just a ‘nobody’ helping to get these huge buildings built,” explains Russ Berry, president of A.S.S.T., which specializes in complex surface fabrications and casework packages for commercial clients. “You’re not really part of the critical path; you’re just part of this big thing called ‘interior finishes.’ Whereas in a house, the people putting in the countertop are really important – they’re like the rock stars.

Working Behind The Scenes

In fact, Berry continues, while the homeowner often works closely with her countertop fabricator in the selection of materials and finishes, the end-user in a commercial setting rarely knows the fabricator has even been on the job. Often, by the time the commercial fabricator is pulled into the project most decisions regarding material and color selection, textures and finishes have long since been made. “There’s some anonymity to it that I kind of enjoy,” he says.

Berry says that, just as in residential fabrication, the depth, breadth and scope of commercial projects can be as different and varied as the clients they serve. “There are commercial projects that are huge, yet incredibly simple,” he explains. “I wish I could say we offer a competitive advantage in situations like that, but we really don’t. We tend to shine on large projects that are complex.”

And shine they do. Among other things, A.S.S.T. is a leading innovator in thermoforming technology and product design. It’s a competency that Berry says has naturally evolved along with the changing needs of his customers. “When you go back far enough in time,” he says, “the head carpenter was often the designer of a building. So the idea of architecture comes from craft and comes from the guys who knew how to build things. The division of labor now has things so spread out, that when we come in and use our skill set and creativity to support a project, an engineer, a designer, and an owner, it seems to suit our interests and abilities.”

The Many Faces Of Commercial Fabrication

Within the commercial sector there are many sub-segments, such as healthcare, hospitality, corporate and educational/institutional. Each of those segments tends to have its own set of unique characteristics. “You can be certain if you’re in hospitality and in lodging that there are some truths,” Berry explains. “For example, quite often – except for the extremely high-end parts of that market segment – they’re refurbishing their buildings every three to five years. So the life expectancy of their product is something that you have to cater to with that customer. Whereas in the education segment, they’re looking for aesthetics and durability.”

“The area that we’re doing most of our work in is in corporate projects,” he continues. “Especially for higher-end businesses that are really heavily branded, there’s a real opportunity to understand the corporate brand and listen to what the customer wants – then come up with solutions that accommodate and support their brand. That’s where A.S.S.T. has really found some traction.”