Gearing up to process material by purchasing digital equipment is one thing; maximizing the efficiency of those expensive pieces of machinery can be quite another. Often it comes down to measuring performance, evaluating the causes for inefficiency and coming up with a plan to address those inadequacies.

Just ask Scott Hanes of Majestic Marble & Granite in Orlando, Florida. Orlando is one of the most price-competitive markets in the country, which is one of the reasons Hanes opted to digitize his shop. “We took our digital transformation and put that out there as a marketing tool to show our customers we are different from other fabricators,” Hanes says.

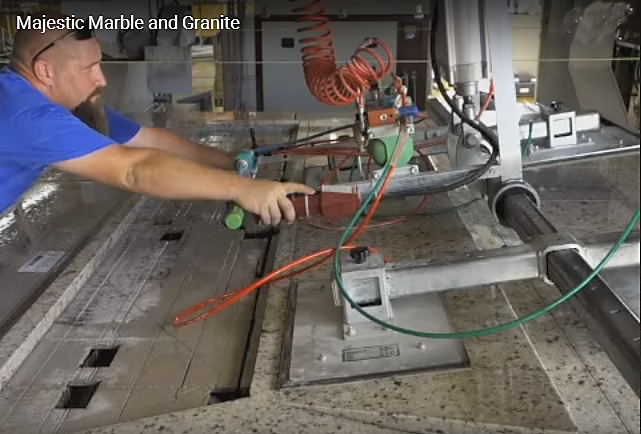

As part of the digital transformation Majestic Marble & Granite had installed a Titan CNC from Park Industries and was enjoying the benefits of increased output combined with consistently high quality of finished product. Increased capacity led to more sales, which led to a bottleneck at the CNC. The solution, according to both the programmer and the operators running the CNC, was to purchase an additional machine.

“So I asked them how much downtime we were experiencing with the Titan,” Hanes explains. “They really didn’t know because there was no data to go on, but they felt it was basically running all the time. We put in place a measurement system to find out. What we found is that over a 12-hour shift the machine was down an average of six hours.”

Further investigation revealed the downtime culprit to be the amount of time it took to change out from one job to the next. Armed with that knowledge the company instituted time studies, which consisted primarily of observing how the machine was being used and calculating the time spent in each operation.

“We found that the majority of that downtime was due to the operators walking up and down the stairs carrying pods and hooking up them up on the back of the table,” says Hanes. “We also noticed that the pods in the front of the table were being loaded two to three times faster because all the operator had to do was stand on the steps, reach down, grab the pods and hook them up. So we did an experiment where we only loaded the front of the table.”

Immediately, changeover times went from 30-45 minutes per job, to between six and seven minutes each. By loading only half the machine at a time and utilizing just the front end of the machine which was quicker and easier to work on, changeover times dropped from six hours per shift to an average of 2 1/2 hours.

“We were actually able to process more square feet on the machine than if we had used both sides,” Hanes explains. “The big picture is you can make incremental improvements with better tools, but that wasn’t the cause of this problem. The bigger piece of that pie is the downtime. Sometimes people will spend a lot of money on equipment and tools when the solution is easy and it doesn’t cost them anything.”

That’s the good news. The even better news is that a few months down the road Majestic’s sales continued to mushroom, necessitating the purchase of a second Titan CNC. Implementing Lean Principles in managing bottlenecks became an even greater priority as the company focused on getting the most out of its equipment. “Optimum layout of the machines and continued focus on downtime has allowed us to go from two 12-hour shifts to two eight-hour shifts, while increasing production by 33%,” Hanes says. “The big kicker is the (employee) head count stayed the same and the labor hours were actually reduced.”

To hear Scott talk about going digital in their countertop business, Listen to StoneTalk »