“I was in awe when I saw it,” explains Waddell. “When I got back home to Tupelo I started doing research on stone countertops. I looked at the competition in the area, and decided there was an opportunity there. It took about two years to get everything lined up, then I jumped into stone fabrication with both feet.”

“Send Me A Truckload!”

So enthusiastic, in fact, was Waddell’s foray into hard surface fabrication that he had a truckload of Cambria delivered to his facility before the machinery to process the material had even been installed. “Cambria controlled fabrication very closely at that time – and still does – but there was a hole in the market in this part of Mississippi that we were willing to fill,” Waddell recalls. “Nobody else was willing to put that kind of investment into the market – so Cambria gave us the opportunity.”

Then, three years ago, Cambria’s fabricator in Memphis went out of business and Premier moved in to fill the void. “We were able to take over that market” Waddell says, “so we now have part of Arkansas, part of Tennessee and part of Mississippi. This year we became a Lexus partner with Cambria. That’s a pretty big deal. There are only 16 Lexus Partners and we are the 16th partner.”

Building Relationships

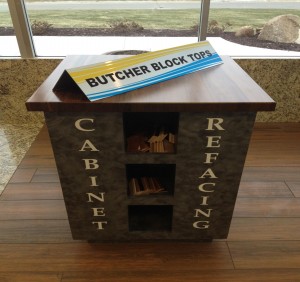

Today, Premier Countertops fabricates all types of quartz surfacing and natural stone countertops for a mostly residential market – although the company has set its sights on bringing in more commercial work in the future. The company has two showrooms, one in Tupelo and the other in Olive Branch, which is just outside of Memphis. And, as a fabricating partner for Cambria, Premier sells fabricated product to other fabricators in its market area.

With customers all along the value chain, Waddell understands the importance of creating and maintaining relationships with everyone in the industry. “A lot of people look at other fabricators as competition,” he says. “I look at them as competition, too, but I also look at them as friendly competition and I build relationships with them. If they have a fabrication question, I do what I can to help.”

Want to know more? At Moraware, we make software for countertop fabricators. CounterGo is countertop drawing, layout, and estimating software. JobTracker is scheduling software that helps you eliminate the time you waste looking for job folders. RemnantSwap is a free place to buy and sell granite remnants with fabricators near you.