I was lucky enough to be a speaker at Park Industries‘ Digital Stoneworking Expo in St. Cloud, MN last week. This was the largest Stoneworking Expo in the years that Park has been hosting them. It was great to see so many fabricators interested in CNC technology, digital templating, and scheduling and estimating software. As usual, I learned a ton from the other speakers. Here’s a short summary of the day.

Evaluating your shop’s performance

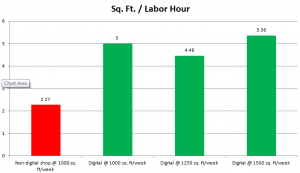

First, Rob Bromley from Park Industries outlined key measurements for evaluating your countertop shop. Based on his analysis, the two metrics that matter most are square foot per labor hour and cost per square foot.

Rob works with many shops that have made the transition from hand-tooling, stick templates, and stacks of paper to fully automated shops. He presented how the metrics changed for a few of his customers, with the adoption of technology.

For this customer, the production efficiency went up from around 2 sq. ft per labor hour to around 5. At the same time, the total cost per sq. ft. (including both labor and machine cost) went from over $9/sq. ft. to $5 or less. And, Rob said that these results are typical of the transformation he’s seen.

Digital fabrication from start to finish

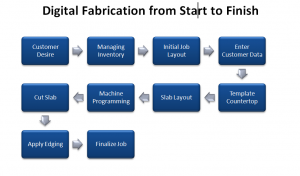

Next, Matt Binsfeld covered the entire workflow through a typical countertop shop. Each of the steps could be it’s own blog post, but it all starts with the customer’s desire for a new or updated countertop.

After the customer finds your countertop company (on the web, most likely), they’ll look at your inventory, get a countertop drawing and estimate, and finally commit to the job. Then it’s up to you to manage all of their job information and schedule.

The next steps are creating a template, laying out the slabs, and programming the machines. In the Park training center, they showed how it’s done when you’re using a CNC saw/waterjet for cutting the slabs and a CNC router for applying edges.

Because of the large crowd at the expo, we were sitting on one side of the training center and the machines were on the other side. I really thought it was cool how Matt would click a button on his computer and things would start happening on the machines – a flash would go off at the photo station, or the CNC’s would start cutting.

Digital Technology Transformation

Next, Stuart Young from the Granite Shop in Calgary told his story. I wrote about this in some detail, when I attended a previous Stoneworking Expo. One of the things that was different this time, is that Stuart dove into his Moraware JobTracker over the web, to show everyone in the audience what his shop was doing that day.

He’s been able to transform his countertop company through automating the office & shop. Of course, he’s also been able to hire great employees that he trusts to run things when he’s gone.

The Results…

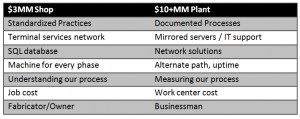

Paul Menninger of Capitol Marble & Granite in Richmond, VA spoke about understanding the bottom-line impact of digital technology on his business.

Paul’s presentation was shockingly honest and open about the metrics in his business. He revealed detailed financials, and showed graphs of his revenue, production efficiency, and labor costs. He uses Moraware JobTracker for tracking his schedule and job information, then takes all of that operational data to the next level with analysis in his own spreadsheets. He’s got a good handle on his business so that he can accurately predict his revenue over the next month or two.

One of his slides really resonated with me. It showed two major walls where his business changed significantly, and forced him to adopt new systems and processes.

In order to get beyond revenues of $3 million, he had to adopt standardized practices and start to understand the overall process. At that point he was still involved in the day-to-day fabrication. Then, in order to grow beyond $10 million, Paul has made the transition to being a businessman.

Sharing with other countertop fabricators

But, one of the most important parts of a seminar like this is being in a room with other countertop fabricators who want to learn from each other. Thanks!

Want to know more? At Moraware, we make software for countertop fabricators. CounterGo lets you draw, estimate, and layout countertops in just minutes. JobTracker is scheduling software that helps you eliminate the time you waste looking for job folders. RemnantSwap is a free place to buy and sell stone remnants with fabricators near you.